Recently, exciting news has emerged from the chemical equipment sector — the research results on the first application of the patented technology "Evaporative Condenser" by Henan Jiuye Chemical Equipment Co., Ltd. in alumina evaporation units have been officially published in Light Metals, an authoritative journal in the industry. This is not only an authoritative certification of Jiuye Chemical's hard technical strength, but also provides a replicable "Jiuye Solution" for the alumina industry to solve energy-saving transformation problems and achieve green transformation.

Guangxi Case Verification: Composite Heat Exchange Technology Breaks Traditional Bottlenecks!

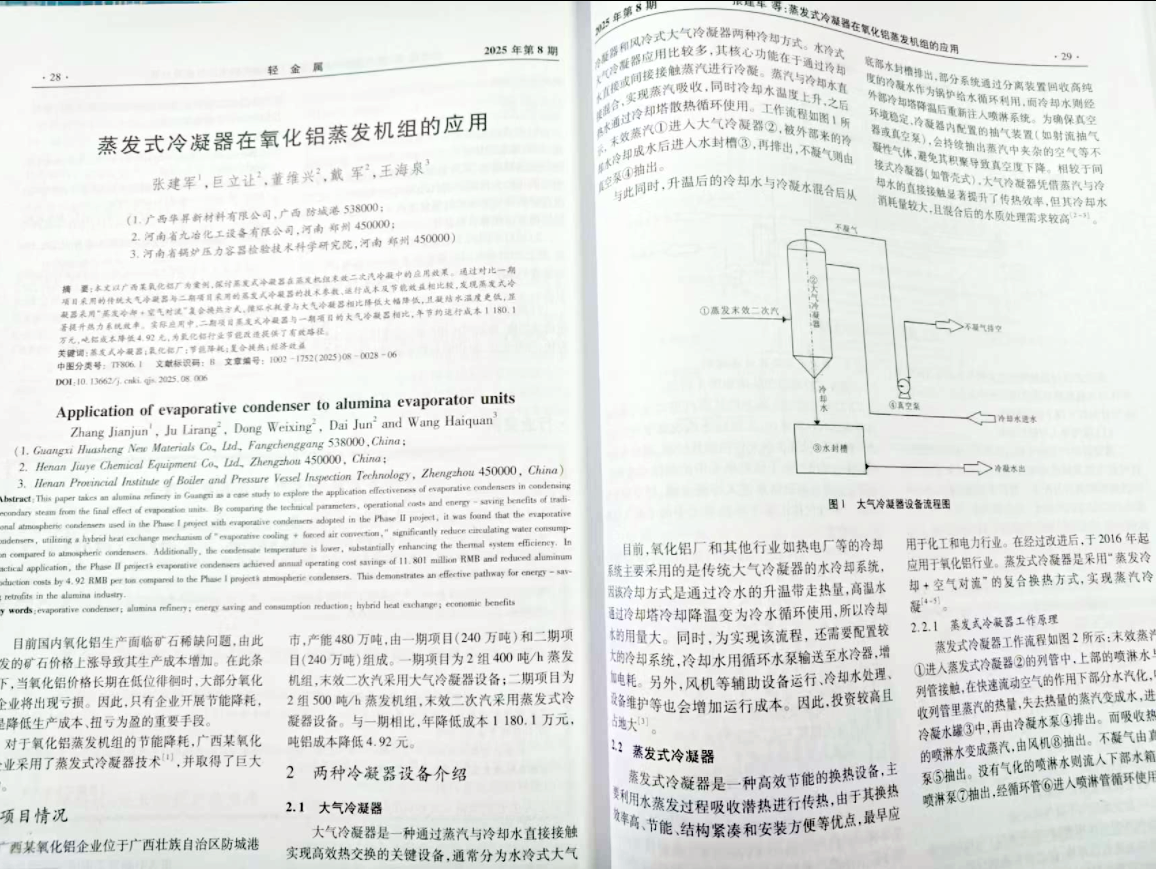

This paper takes a large-scale alumina plant in Guangxi as a practical sample, focuses on the application effect of the evaporative condenser in the secondary steam condensation process of the final effect of the evaporation unit, and intuitively presents technological breakthroughs with data through a comprehensive comparison with the traditional atmospheric condenser used in the Phase I project of the plant.

Jiuye Chemical's evaporative condenser innovatively adopts the "evaporative cooling + air convection" composite heat exchange technology. Compared with traditional equipment, it not only greatly reduces the circulating water consumption, but also controls the condensate water temperature within a lower range, directly promoting a significant improvement in the operating efficiency of the entire thermal system and breaking the performance bottlenecks of traditional condensers in terms of technical principles.

Outstanding Economic Benefits: Tens of Millions of Yuan in Annual Cost Savings, with Solid Evidence for Cost Reduction and Efficiency Improvement

From the perspective of economic benefits, which enterprises care about the most, the results of this technology's implementation are truly remarkable. Data shows that after the plant's Phase II project adopted Jiuye's evaporative condensers, compared with the traditional atmospheric condensers used in the Phase I project, it can save 11.801 million yuan in annual operating costs. When converted to the production cost per ton of aluminum, this directly reduces the cost by 4.92 yuan. For alumina enterprises with large production scales, this cost reduction translates to a substantial increase in profit margins. It further confirms the core value of Jiuye's evaporative condensers in "cost reduction and efficiency improvement" and provides a highly referenceable practical model for energy-saving transformations across the entire industry.

24 Years of In-depth Cultivation: Qualifications and Hardware Solidify the Foundation of Quality

As a "veteran" deeply engaged in the chemical equipment sector for 24 years, Jiuye Chemical has always regarded "technological innovation" as its core competitiveness since its establishment in 1999, gradually growing into a comprehensive high-tech enterprise integrating scientific research, design, manufacturing, installation, and services.

To ensure product and project quality, the company has built a sound quality and safety management system. It has successively obtained certifications for the ISO 9001 Quality Management System, ISO 14001 Environmental Management System, and GB/T 28001 Occupational Health and Safety Management System. Additionally, it holds design and production licenses for Category I and II pressure vessels, and is equipped with professional physical and chemical testing as well as non-destructive testing equipment—comprehensively solidifying the quality defense line from qualifications to hardware.

Fruitful R&D Achievements: Nearly 40 Patents Lead the Industry

On the path of R&D and innovation, Jiuye Chemical has never ceased its efforts. Up to now, the company has obtained nearly 40 national patents, including the "Seven-effect Sectional Evaporator Unit for Concentrating Sodium Aluminate Solution", and a number of its technological achievements have been appraised by the Chinese Academy of Sciences (CAS) as reaching the "internationally leading level".

Looking back on its technological development, in 2016, the company's independently developed 400 tons per hour "Seven-effect Two-stage Split-type Falling Film Evaporator" was successfully put into operation, filling the relevant technological gap at home and abroad in one fell swoop. Moreover, this successful application of the evaporative condenser in the alumina evaporation unit marks another milestone in its technological iteration and upgrading.

Market Verification Passed: Multiple Projects Validate Technology Stability

In fact, this patented technology has long undergone market verification: Previously, when put into use in enterprises such as Luoyang Rhinehide and Luoyang Zhongchao New Materials, the equipment's annual vacuum degree remained stable at -0.088MPa, and its operational reliability was widely recognized. In the Phase II alumina project of Guangxi Huasheng New Materials Co., Ltd., Jiuye's seven-effect falling film evaporator and the new-type evaporative condenser "work in synergy", enabling the final-effect evaporation vacuum degree to reach -0.09MPa, which surpasses the design indicators. This saves 12.6 million kWh of electricity annually and verifies the stability and efficiency of the technology again.

Another Technological Breakthrough: From "Seven-effect" to "Eight-effect", Leading the Global Industry Upgrade

In recent years, Jiuye Chemical has accelerated its pace of technological innovation: it has not only successfully developed the world's first eight-effect evaporator, but also officially signed a contract for the Indonesia alumina project.

The iteration from "Seven-effect" to "Eight-effect" is not a simple addition of effects, but an in-depth optimization and reconstruction of evaporation technology. The implementation of this technology will surely push the evaporator technology in the alumina industry to a new level and inject new impetus into the development of the global industry.

Dual-Wheel-Driven Strategy: In-depth Cultivation of the Domestic Market and Expansion of the Overseas Market

Today, Jiuye Chemical has entered a dual-wheel-driven phase of "deeply cultivating the domestic market and expanding overseas": In the domestic market, its equipment has won the trust of many enterprises with its solid quality; in its overseas layout, the new Tongzhou Bay factory, with a total investment of over 100 million yuan, has started construction. In the future, relying on port advantages, it will further radiate to core markets such as Southeast Asia and the Middle East, providing efficient and energy-saving chemical equipment solutions for global customers.

Looking to the Future: Empowering Global Industries with the Power of Innovation

Looking ahead, the publication of the evaporative condenser's application achievements in the industry's authoritative journal is not only another recognition of Jiuye Chemical's technical strength, but also a new starting point for its continuous leadership in driving the industry's development.

In the future, Jiuye Chemical will continue to be guided by the principle of "innovation-driven and green development", deepen its engagement in the chemical equipment sector, and continuously develop more efficient, energy-saving, and environmentally friendly technologies and products. It will inject "Jiuye Strength" into the sustainable development of the alumina industry and even the global chemical industry, thus continuing to lead the industry toward new heights of high-quality development.