Amidst the increasingly fierce competition in the chemical equipment industry, the success of every project is inseparable from exquisite technology and the determination to overcome difficulties. Recently, Henan Jiuye Chemical Equipment Co., Ltd. has brought encouraging news – as the EPC general contractor for the Jingxi Evaporation Station Project, Jiuye Chemical has not only completed the design and manufacturing of the project, but the Phase III Evaporation Station of the Jingxi Tiangui Project built by it has also delivered an impressive performance of exceeding the task target during commissioning and operation. Among them, the high-concentration evaporator adopted in the project has played an indispensable role, demonstrating the company's strong core strength through solid achievements!

Over-target operation, data testifies to strength.

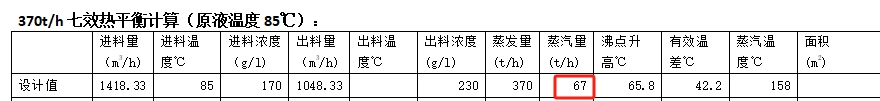

The original design of the project specified a steam quantity of 67 tons and a water evaporation capacity of 370 t/h. This design indicator is already at a relatively high standard in the industry, serving as a scientific target formulated by Jiuye Chemical during the design and manufacturing stages, based on its accurate grasp of project requirements and its own profound technical accumulation. However, in the actual operation process, relying on the excellent performance of the high-concentration evaporator, the Phase III Evaporation Station of the Jingxi Tiangui Project has unleashed energy far beyond expectations. According to detailed operation data statistics, calculated based on the raw liquid feed rate and inlet-outlet concentration, the water evaporation capacity has exceeded 10%. These rising sets of data are not only a leap in numbers, but also a strong proof of Jiuye Chemical's comprehensive strength (integrating design, manufacturing and EPC general contracting), top technical level and solid project quality, fully demonstrating the project's strong production potential.

Technology empowers and safeguards overproduction.

design parameters

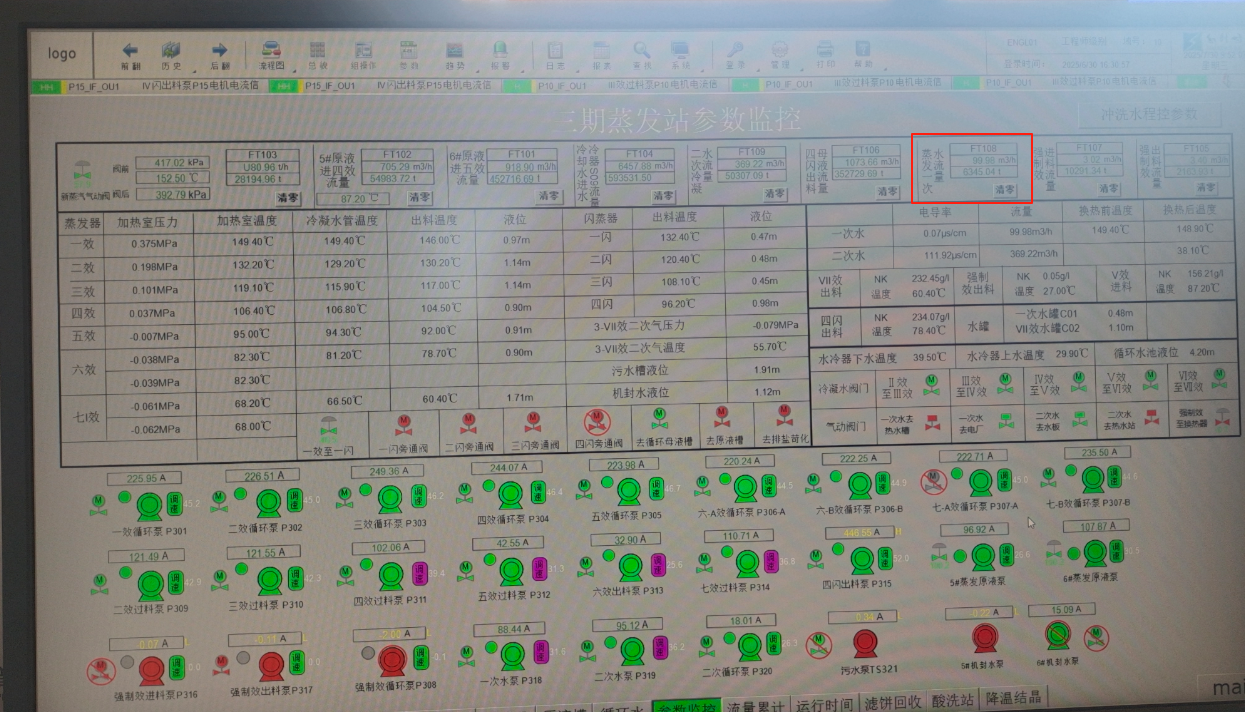

operating parameters

Such remarkable overproduction results are not accidental, but stem from strong technical support. Henan Jiuye Chemical Equipment Co., Ltd. made bold innovations in this project, adopting 5-60Hz constant torque variable frequency motors in feed pumps, discharge pumps, circulation pumps, and water pumps for the first time.

This type of motor has unique performance advantages: it can maintain constant torque output within the wide frequency range of 5-60Hz. This means it can flexibly adjust its operating status according to production needs, functioning stably whether under low-load or high-load conditions. It perfectly cooperates with high-concentration evaporators, providing continuous power for the efficient operation of the equipment.

In the process of the project pursuing overproduction, with its excellent adaptability and reliability, this motor has become a key technical guarantee for achieving the overproduction target. It enables the equipment to remain stable and efficient even in an operating environment with high steam volume, laying a solid foundation for output improvement. Moreover, the operating frequency of the 4th flash discharge pump currently reaches 53Hz!

Meanwhile, Henan Jiuye Chemical Equipment Co., Ltd. also introduced an online caustic soda intelligent measurement system in this project, successfully replacing the traditional isotope densitometer and realizing nuclear-free production. This breakthrough is of great significance in the industry.

The application of this system is an important manifestation of the project's intelligent upgrading. Working in synergy with high-concentration evaporators, it has further improved production efficiency. In chemical production processes, the accurate measurement of inlet and outlet material concentrations is crucial, as it directly affects the regulation of production processes and the quality of final products.

The online caustic soda intelligent measurement system can monitor and measure inlet and outlet material concentrations in real time and accurately, minimizing possible errors in traditional manual measurement and providing production operators with precise data references. Based on these accurate data, various parameters in the production process can be adjusted in a timely and effective manner, thereby achieving a significant improvement in production efficiency and providing strong technical support for the project's over-target operation.

A flood of acclaim, and strength wins recognition.

High-quality project outcomes have naturally earned high recognition from partners. As the implementer integrating design, manufacturing and EPC general contracting for the Jingxi Evaporation Station Project, Henan Jiuye Chemical Equipment Co., Ltd. has seen the over-target operation of the Jingxi Tiangui Phase III Project under its charge win unanimous praise from the Tiangui Project team, thanks to its stable performance, efficient output and reliable quality.

They have all stated that Jiuye Chemical demonstrated professional technical proficiency and a rigorous work attitude during the project implementation. Excellence was pursued in every link, from design and manufacturing to general contracting management. The over-target operation of the project not only meets actual production needs, but also provides greater flexibility and possibilities for subsequent production plans.

The success of the Jingxi Tiangui Phase III Project this time is a model for Henan Jiuye Chemical Equipment Co., Ltd. to deeply integrate design, manufacturing and EPC general contracting, and drive practical application through technological innovation. In the future, Jiuye Chemical will continue to adhere to the concept of technological innovation, continuously explore the application of cutting-edge technologies in the field of chemical equipment, repay customers and society with better products and services, stand at the forefront in the development tide of the chemical industry, and create more remarkable achievements!