I. Equipment Structural Composition

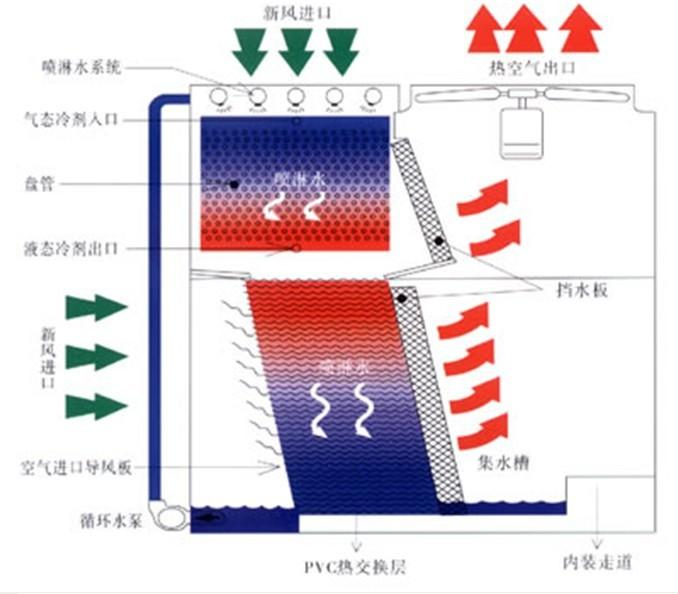

Evaporative condensers consist of three core components with clear functions:

1. **Top Ventilation System**: Equipped with induced draft fans or exhaust fans, which drive air flow through mechanical power to provide the necessary air flow conditions for heat exchange inside the equipment, ensuring ordered air circulation within the device.

2. **Middle Heat Exchange Unit**: The heat exchanger, as the core component of the equipment, undertakes critical heat exchange tasks. It adopts a shell-and-tube structural design, where the secondary steam to be treated flows through the tube side, while the external heat exchange process occurs in the shell side, achieving heat transfer between the steam and the external environment.

3. **Bottom Water Storage Unit**: The water tank is responsible for storing spray water, which is delivered to the top of the heat exchanger through a circulation water pump to provide a stable water source for the continuous heat exchange process.

II. Detailed Explanation of the Working Principle

The operation of an evaporative condenser is based on the principles of efficient heat exchange and phase change, with the specific process as follows:

1. **Steam Introduction**:

Secondary steam generated from the final effect of industrial production is introduced into the tube side of the heat exchanger. As the object of heat exchange, it awaits heat release and a change in state.

2. **Spray Cooling**:

Water from the water tank is delivered to the top of the heat exchanger through a circulation system and uniformly sprayed onto the outer surface of the heat exchanger (shell side) via a spray device, forming a continuous water film that comes into direct thermal contact with the steam in the tube side.

3. **Air Heat Exchange**:

An induced draft fan introduces unsaturated air from the outside into the equipment through the air inlet. As the air flows upward along the outer surface of the heat exchanger, it fully contacts the water film. The unsaturated air absorbs moisture from the water film and gradually becomes saturated, a process accompanied by the phase change of liquid water to water vapor. Since the phase change requires absorbing a large amount of heat, this heat is directly sourced from the secondary steam in the tube side.

4. **Steam Condensation**:

After losing heat, the secondary steam undergoes a phase change from gas to liquid, completing the condensation process. As the steam continues to condense, the amount of gas inside the equipment decreases, and the pressure drops, thereby creating a stable vacuum environment that provides the necessary pressure conditions for industrial production processes.

III. Heat Exchange Mechanism of Saturated Air

Even saturated air still possesses heat exchange capacity in evaporative condensers. After saturated air enters the equipment, it comes into contact with the high-temperature surface of the heat exchanger during its upward flow and is heated. As the temperature rises, the upper limit of the air's saturated humidity increases, transforming the originally saturated air into an unsaturated state and restoring its ability to absorb moisture. This allows it to continuously participate in the heat exchange process, ensuring the continuity and stability of heat exchange in the equipment.

IV. Customized Design Features

Due to significant differences in meteorological conditions across regions, including variations in parameters such as air humidity and temperature, the design of evaporative condensers must fully account for regional characteristics. During the design process, key parameters such as air induction volume and heat exchange area must be accurately calculated and determined based on local meteorological data. Through customized design, the equipment is ensured to achieve optimal operational performance under different environmental conditions, providing reliable heat exchange and vacuum control for industrial production.

Evaporative condensers have become indispensable equipment in modern industrial production by virtue of their high heat exchange efficiency, stable vacuum maintenance capability, and flexible customized design advantages. With the continuous development of industrial technology, their application scope and technical performance are expected to be further expanded and improved, playing a greater role in ensuring efficient and stable production across various industries.