The advent of the eight-effect evaporator represents a profound innovation in traditional evaporator technology. Aiming at the challenges of high difficulty and high energy consumption in evaporating low-concentration mother liquor (caustic alkali concentration ≤ 215g/L) during alumina production, the eight-effect evaporator has achieved a qualitative leap in evaporation efficiency through increasing the number of effects, optimizing temperature difference distribution, and conducting thermal balance calculations and designs. In terms of thermal balance and temperature difference matching, the eight-effect evaporator strictly controls the temperature difference of each effect within 3 - 4°C. This design ensures that its effective temperature difference is basically equivalent to that of the seven-effect evaporator under high-concentration operating conditions (mother liquor concentration ≥ 240g/L). The seemingly subtle temperature regulation is, in fact, the result of numerous experiments and precise calculations, guaranteeing the stable operation of the system. The stable and reliable operation of the fourteen high-concentration seven-effect evaporators successfully implemented by Jiuye Chemical Engineering in China provides strong support for the stable operation of the eight-effect evaporator under low-concentration conditions.

Precise and scientific thermal balance calculations and the rational allocation of the area of each effect are the core technical innovations of the eight-effect evaporator. Compared with the seven-effect evaporator, the eight-effect evaporator places more emphasis on the cascade utilization of heat in its design. When the seven-effect evaporator processes low-concentration mother liquor, it often suffers from significant heat loss and insufficient steam utilization. In contrast, the eight-effect evaporator extends the heat transfer path by adding one more effect, enabling a more thorough utilization of the latent heat of steam. With years of accumulated rich calculation and design experience, Jiuye Chemical Engineering can accurately control the heat transfer and material conversion during the operation of the equipment, thus optimizing the performance of the evaporator.

From the perspective of risk control, the eight-effect evaporator is also more comprehensively designed. In actual production, if one effect malfunctions, the eight-effect evaporator can quickly isolate the faulty effect and switch to the operation mode of a seven-effect evaporator group. At this time, due to the increase in the total area of the entire evaporator group, the operating load of the remaining seven effects is relatively reduced, making the system operation more stable and reliable. This flexible operation mode significantly reduces production risks compared with traditional seven-effect evaporators, which may cause production interruptions or a significant drop in efficiency when a failure occurs.

II. Remarkable Energy-saving Benefits: The Enormous Potential Behind the Data

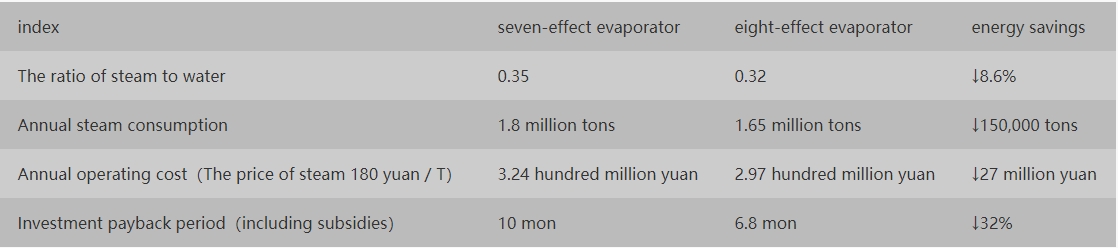

The advantages of the eight-effect evaporator in energy conservation and consumption reduction are particularly evident through specific data comparisons. The results of thermal balance calculations show that the steam-to-water ratio of the eight-effect evaporator group can be reduced by approximately 0.03 compared to that of the seven-effect evaporator group. Although this figure may seem small, it holds enormous energy-saving potential. Taking an alumina plant with an annual output of 1.2 million tons and equipped with a 600 t/h evaporator as an example, a detailed energy consumption comparison analysis is carried out as follows:

In China, based on the steam price of 180 yuan per ton, the annual steam cost savings achieved by using the eight-effect evaporator can reach as high as 27 million yuan. In regions with high steam prices, such as Guinea (where liquefied natural gas or heavy oil is commonly used as fuel in boilers, and the steam price exceeds 300 yuan per ton), for alumina plants of the same scale, the annual steam cost savings using the eight-effect evaporator can reach 45 million yuan. This indicates that in regions with high steam costs, the annual energy expenditure savings provided by the eight-effect evaporator for enterprises is almost equivalent to the investment required to build a small-scale alumina production workshop.

III. Outstanding Economic Benefits: A High-return Investment Option

In terms of economic benefits, the eight-effect evaporator also demonstrates strong competitiveness. Although the investment in a 600t/h eight-effect evaporator group is approximately 25 million yuan higher than that of a seven-effect evaporator group (covering equipment, steel structures, installation, and instrumentation and electrical control systems), from the perspective of long-term operating costs, this investment is extremely valuable. Thanks to the remarkable energy-saving effect of the eight-effect evaporator, the production cost of alumina can be reduced by 37.5 yuan per ton. Calculated based on a steam price of 300 yuan per ton, the annual operating income, that is, the energy-saving income, can reach 45 million yuan, and the investment payback period is less than seven months (excluding government energy-saving subsidies). In contrast, under the same production scale, the seven-effect evaporator not only has higher energy consumption costs but also a longer investment payback period. The extremely high return on investment of the eight-effect evaporator can quickly bring substantial economic returns to enterprises and help them gain a competitive edge in the market.

IV. Sound Patent Portfolio and Intellectual Property Protection: A Solid Backbone for Technological Leadership

Jiuye Chemical Engineering attaches great importance to the intellectual property protection of the eight-effect evaporator and has established a comprehensive patent portfolio. Currently, the patent titled "Eight-effect Two-stage Cross-flow Evaporator Group for Concentrating Sodium Aluminate Solution" (Patent No.: ZL 2013 2 0620522 2) has been successfully applied for. Meanwhile, three patents are under application, namely "Eight-effect Multistage Evaporator Group for Sodium Aluminate Solution" (Patent Application No. for Invention Patent: 202510473827.2), "Eight-effect Two-stage Evaporator Group for Sodium Aluminate Solution" (Patent Application No. for Utility Model Patent: 202520714213.4), and "Eight-effect Three-stage Evaporator Group for Sodium Aluminate Solution" (Patent Application No. for Utility Model Patent: 202520714415.9). These patents comprehensively cover the core technologies of the eight-effect evaporator, clearly distinguishing them from the patent technologies of the seven-effect evaporator. They not only protect the company's own technological innovation achievements but also build a solid technical barrier for the eight-effect evaporator in the market competition, ensuring its leading position in technology.

In conclusion, the eight-effect evaporator demonstrates remarkable advantages in the evaporation of low-concentration alumina mother liquor. In terms of technical feasibility, operational stability, energy-saving benefits, and economic efficiency, it far surpasses traditional seven-effect evaporators. Additionally, the comprehensive patent portfolio provides strong support for its sustained development. The eight-effect evaporator is undoubtedly an ideal choice for alumina production enterprises to reduce costs, increase efficiency, and upgrade their technologies. It will strongly propel the alumina industry towards a more efficient and environmentally friendly future.

Contact Us

Product

Contact Us